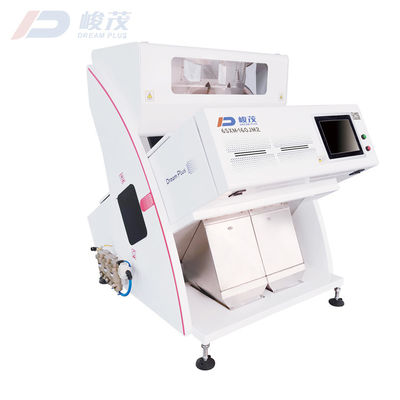

Full Color CCD Broken Rice Color Sorter 160 Channel

Product Details:

| Place of Origin: | Anhui China |

| Brand Name: | DREAM PLUS |

| Certification: | CE、SGS、ISO9001 |

| Model Number: | JM2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Fumigated Wood Package |

| Delivery Time: | 7-15 Working Days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 Set/Sets per Month |

|

Detail Information |

|||

| Model: | 6SXZ-160JM2 | Channel: | 160 |

|---|---|---|---|

| Capacity: | 1.5-3t/h | CCD: | Full Color,5400pixels |

| Warranty: | 1 Year | Filter Brank: | ARK |

| Illumination System: | LED | After-sales Service: | Machine Commissioning And Training |

| Opertation System: | Windows 7 | Ejector Cycle: | 2 Billion |

| Voltage: | 220v/50Hz | ||

| Highlight: | Broken Rice Color Sorter,Full Color Ccd Rice Color Sorter,160 Channel Ccd Color Sorter Machine |

||

Product Description

Broken Rice Color Sorter

Rice Color Sorting Machine

| Model | 6SXM-160JM2 |

| Channel | 160 |

| Capacity(t/h) | 1.5-3 |

| Carryover Rate(bad:good) | >10:1 |

| Sorting Accuracy(%) | ≥99.99 |

| Voltage (v/hz) | 220/50 |

| Power Supply(kw) | ≤2.5 |

| Air Consumption(m3/min) | 1.2 |

| Pressure(Mpa) | 0.5-0.8 |

| Weight(kg) | 600(±5%) |

| Diamension(mm) | 1330*1630*1550 |

Sorting Material

![]()

Technical Features

Advanced circuit design of these machines ensures about their excellent speed frequency level.

Application of cutting edge optical vision technology

Bright lighting quality for accurate detection of color difference

Utilization of high definition CCD image acquisition technology for error free operation

Our Service

1. Before Sale

We will provide detailed solutions for your special requirement and help you know more about our color sorter.

2. After Sale Service

● 7*24 hours

24 hours door to door fast response,7*24hour on-line service.

● On-time arrival

Arrive the customer site on the appointed time.

● Comprehensive maintenance

Do the comprehensive inspection and maintenance of the machine after trouble shooting to ensure good working condition.

● Professional training

Supply fully description of operation and maintenance of color sorter to help you understand the routine maintenance and simple troubles hooting.

● Site cleaning

Clean up machine and service area after trouble shooting.

● Strict Accept

Check the performance with customer after service is completed to ensure the good working condition and best sorting performance.